Our Products

Laminate tubes are made from webs that comprise at least five different layers including the barrier layer. The two longitudinal edges of the laminate are welded together to form the tube body, which is then joined to the tube shoulder with its closure to give a reliable and impermeable seal.

Depending on the product and contents, laminate tubes can have a barrier layer of aluminium, plastic or ceramic and – in the case of transparent laminates – a barrier of polyester. The so-called Polyfoil tube is a specific type of laminate tube in which a plastic layer is extruded on top of the laminate.

Laminate tubes combine the beneficial properties of the different materials: excellent barrier effect to protect the contents and high-end print quality using practically all printing techniques to produce that persuasive brand presence at the point of sale. The tube’s new ‘invisible’ weld seams together with the appropriate printing technology allows 360° printing of the tube bodies – all the way round.

Most laminate tubes are supplied for the toothpaste market but they are playing an increasingly more important role for cosmetics and in other fields of application.

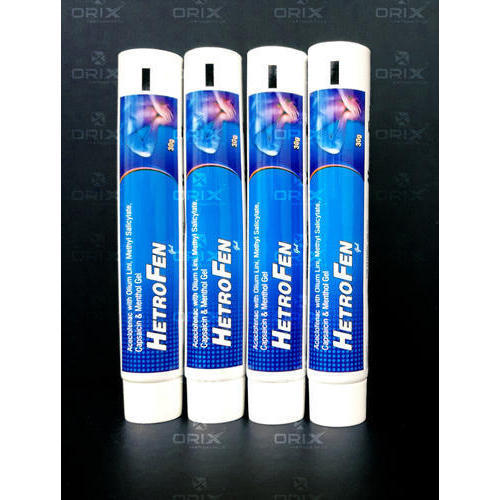

Laminated Tubes are used across the globe for packaging in food, cosmetics, personal care, pharma and industrial applications as they offer a competitive edge in the market. Laminated tubes offer excellent barrier properties and are a cost effective solution to increase products Shelf-life. The flexible, smooth and soft exteriors deliver excellent sealability. Laminate combines the unique benefit of Aluminum tube properties with feel and look of Plastic.

We are looking forward to extend in the manufacturing of Caps & Closure with cavitation ranging from 32 to 64 from hot runner molds developed with some of the worlds’ best mold makers.

Our Quality check system ensures in detail quality checks before being made ready for dispatch. Further, Professional audit is conducted on packed components to ensure reliability of components manufactured at OPPL.